main menu

콘텐츠

Automation System

Automation System  Robot Automation System

Robot Automation System -

Collaborative Robot Automation System

- Teleoperation Avatar Robot System

- AI-Based 3D Scan Automatic Inspection

- CO2 Automatic Welding Robot System

- Laser Automatic Welding Robot

- Product Transfer Robot System

Teleoperation Avatar Robot

Teleoperation refers to the technology that allows a person to remotely control and operate a robot or machine from a distance.

An avatar robot consists of a master robot and a slave robot, which communicate with each other and mimic the movements of the master robot.

This technology can be applied to industrial sites, enabling robots to perform tasks in hazardous industrial environments from a safe location.

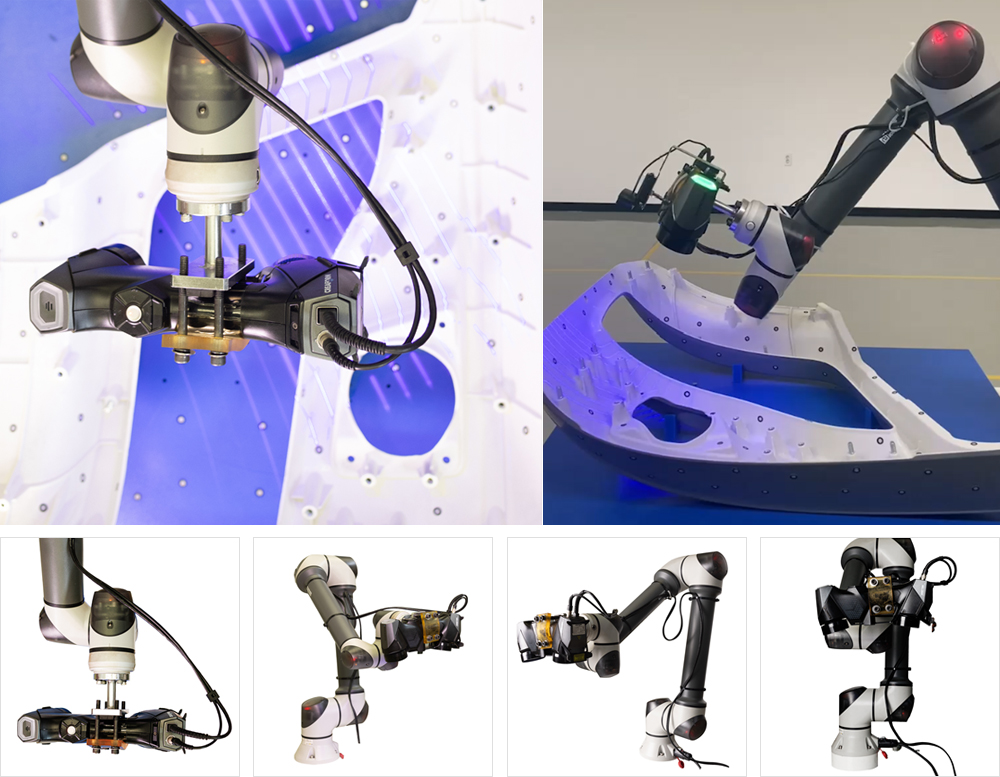

AI-Based 3D Scan Automatic Inspection

This is Korea's first 3D non-contact automatic inspection system that combines 3D scan automatic inspection technology, robot automation technology, and AI technology.

This system is an AI-based 3D scan automatic quality inspection system that uses AI technology to recognize parts and control the robot arm to collect and inspect optimal 3D scan data.

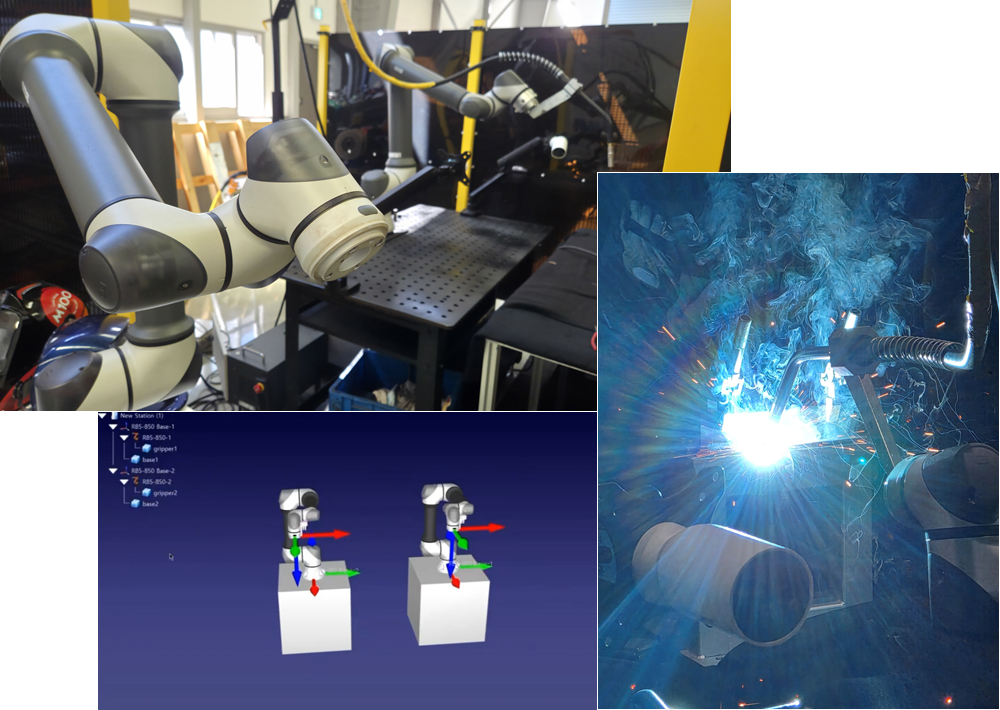

CO2 Automatic Welding Robot System

This CO2 automatic welding system combines CO2 automatic inspection technology and robot automation technology.

This system utilizes collaborative robots to automate CO2 welding tasks performed by human operators. It is a cost-effective automatic welding system optimized for small and medium-sized enterprises facing labor shortages and limited capital.

Automatic Welding System Features

Outstanding Performance and Price Competitiveness through Optimal Components

By utilizing the best core components and developing a system that focuses on reasonable pricing, we have achieved high price competitiveness.

-

Rainbow Collaborative Robot

Rainbow Collaborative Robot

-

CO2 Welder

CO2 Welder

Best Technology and Performance

Existing Technology CO2 Automatic Welding System - CO2 Welding with Industrial Robots

- Robot teaching is difficult and time-consuming

- High risk of safety accidents

- High system construction costs

- Excessive equipment investment and large factory floor space requirements

- Safety equipment required to prevent robot-related accidents

- CO2 Work with Collaborative Robots

- Robot teaching is very easy, and the work time is much shorter than for industrial applications

- Significantly lower risk of safety accidents (collaborative work with workers possible)

- Low system construction costs

- Relatively low equipment investment and factory floor space requirements

- No safety equipment required

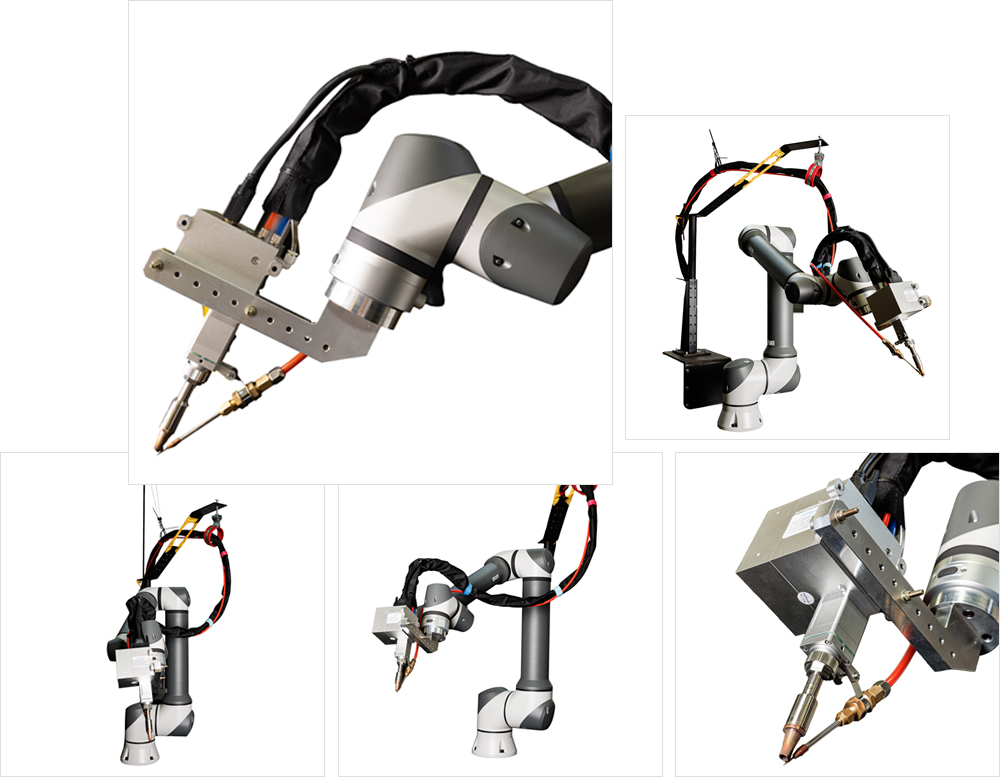

Laser Automatic Welding Robot

This laser automatic welding system combines laser automatic inspection technology and robot automation technology.

This system automates laser welding tasks using collaborative robots instead of human labor. It is a cost-effective automatic welding system ideal for small and medium-sized enterprises facing labor shortages and limited capital.

Automated Welding System Features

Outstanding performance and competitive pricing through optimal component application

Highly competitive pricing achieved through the application of top-of-the-line core components and the development of a system focused on reasonable pricing.

-

Rainbow Collaborative Robot

Rainbow Collaborative Robot

-

Laser Welder

Laser Welder

Best Technology and Performance

Existing Technology Laser Welder System - Laser Welding with Industrial Robots

- Robot teaching is difficult and time-consuming

- High risk of safety accidents

- High system construction costs

- Excessive equipment investment and large factory floor space requirements

- Safety equipment required to prevent robot-related accidents

- Laser Work with Collaborative Robots

- Robot teaching is very easy, and the work time is much shorter than for industrial applications

- Significantly lower risk of safety accidents (collaborative work with workers possible)

- Low system construction costs

- Relatively low equipment investment and factory floor space requirements

Product Transfer Robot System

This automated product transfer system integrates robot automation, robot gripper, and tool changer technologies.

This system utilizes collaborative robots and grippers to automate parts transfer, eliminating the need for manual labor. This cost-effective automated transfer system addresses labor shortages and reduces costs.

-

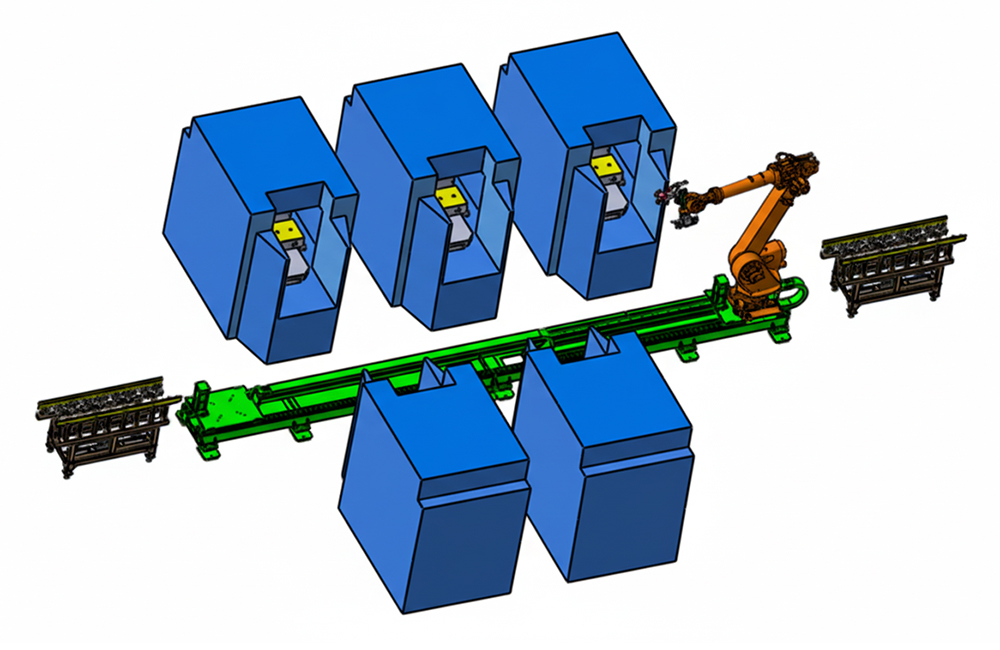

Industrial Robot Automation System

Industrial robots are automated robots programmed to perform repetitive or dangerous tasks in place of humans in manufacturing and industrial environments.

Automated Gas Engine Cylinder Head Machining Process for Generators

System Design